320t Overhead Crane for Foundry | Overhead Crane for Foundry

This 320t overhead crane is the biggest metallurgical foundry crane ever made in Henan Province, China. Main structure of the 320t foundry crane is with 4 girders and 6 rails.

Read More >

This 320t overhead crane is the biggest metallurgical foundry crane ever made in Henan Province, China. Main structure of the 320t foundry crane is with 4 girders and 6 rails.

Read More >.jpg)

This intelligent steel pipe distribution overhead crane is used to distribute steel-pipes in production line before the steel-pipes being sawed. It can transport steel pipes from one roller table to any places intelligently.

Read More >.jpg)

Rail-type container gantry crane is consists of the steel structure, lifting mechanism, micro-transfer mechanism, anti-sway system, travelling mechanism. Container Rail Mounted Gantry Crane can be used in inland terminals, container yard, rail freight station, coastal freight yard and frontier wharf.

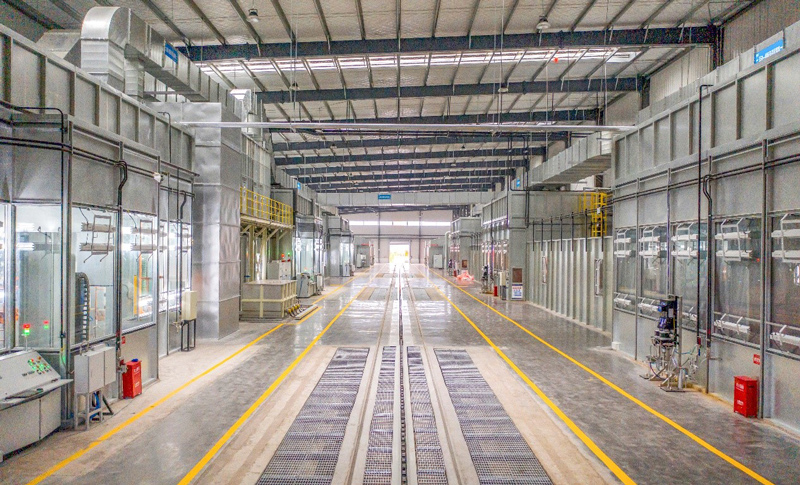

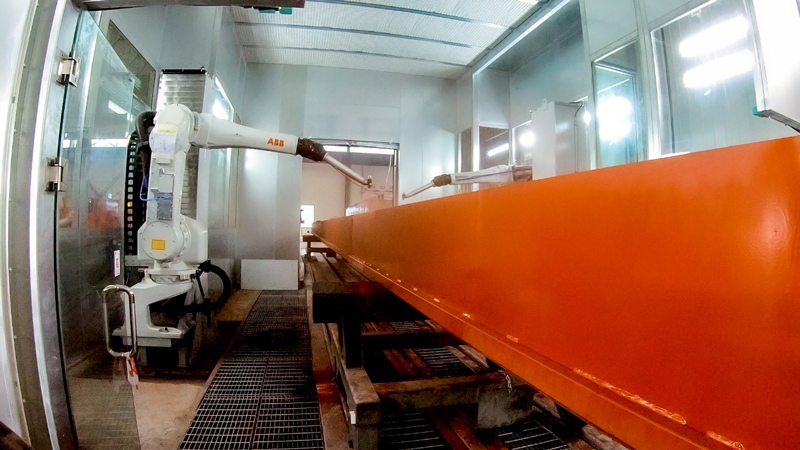

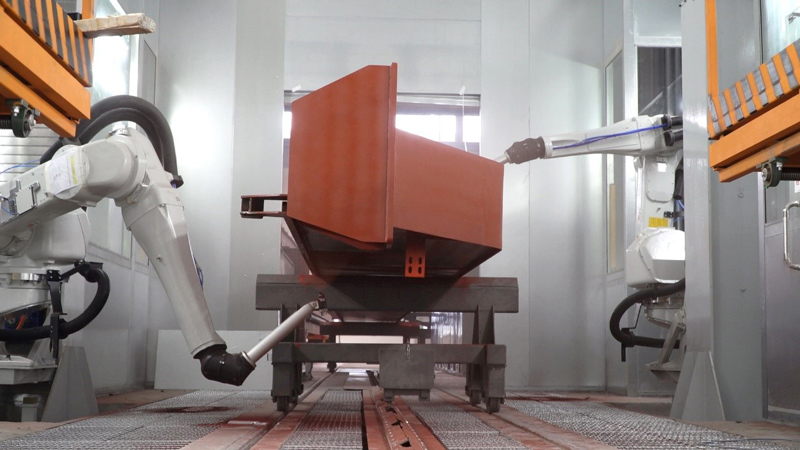

Read More >In recent years, Weihua has taken the lead in the lifting industry to use automatic coating line for large structural parts, and build 6 intelligent coating production lines to carry out emission control from the start, process, and end to achieve intelligent and green production.

Cleaner Environment:

The capture rate of waste paint mist generated in the painting process is more than 95%; the exhaust gas treatment efficiency can reach more than 98%, and the VOC exhaust gas is discharged after reaching the standard; the paint slag is sent to the hazardous waste treatment company for centralized treatment and discharge; equipped with noise reduction measures; The maximum surrounding noise does not exceed 80dB, and the ambient noise of operators does not exceed 85dB. The application of the fresh air system improves the working environment and reduces occupational health hazards.

More Stable:

The production line realizes the full coating process assembly line operation, taking into account the connection of the front and rear processes, the layout is reasonable, the logistics is smooth, and it is convenient to organize production. The intelligent automatic coating production line can complete the coating operation of the main girder of a crane in 30 minutes. Compared with manual operation, the coating production efficiency is increased by more than 8 times.

Energy Saving:

Pre-treatment, spraying, drying, forced cooling and other operating areas are independently and fully enclosed, benefiting from the application of centralized paint conveying system, automatic spraying system and air conditioning circulating air technology, which can effectively reduce the water, electricity, and gas energy consumption, The operating cost of the spraying production line is reduced by about 15% compared with the traditional production line.

Better quality

The coating constant temperature system controls the coating working environment temperature at 23°C±2°C, and the drying room temperature is maintained at 80°C, so that the spray quality is more stable; the application of the constant pressure centralized paint delivery system and the automatic spraying technology makes the spraying finer, Which greatly improve the appearance quality of the product.